Reproduced here with the kind permission of the Editor of Aerospace Manufacturing.

Article in Aerospace Manufacturing, January 2024 issue. View pdf of the article here

Solid-state-based emulators are increasingly replacing floppy drives and other yesteryear storage technologies. Brian McSloy explains how solid-state-based swap-in drives are keeping host system operational and delivering new features.

The aerospace and defence sectors are renowned for the length of service systems and platforms must provide. Not surprisingly there are computer-based systems such as flight simulators, radar systems and automatic test equipment (ATE) stations in service today that were built more than 40 years ago.

Many of these systems were designed to use removable media such as magnetic (floppy) disks, magneto-optical (MO) disks or magnetic tapes. For example, some airlines are currently using Airbus A320 aircraft that had their maiden flights back in the 1980s, when floppy disk was the primary means of data transfer.

These old-technology drives all have moving parts that, over the years, have worn. Their failure might be imminent, potentially resulting in considerable problems when the host system loses its ability to read or write data.

Unfortunately, new replacements are obsolete; superseded years ago by newer technologies such as SD card and USB. Even early generation hard disk drives (HDDs) are now obsolete.

However, it is not just that the original storage devices have become obsolete. Alternatives that use the same physical interfaces are not available either. For example, an extremely popular way of connecting computer peripherals in the 1980s (and through to the early 2000s) was the small computer system interface (SCSI, “scuzzy”). It was standardised in 1986 as the SCSI parallel interface (SPI) 8-bit wide, single-ended bus. The standard evolved through a number of iterations, doubling the number of data lines to 16 and incorporating differential signalling (allowing the transfer rate to significantly increase) before finally being superseded by the serial attached SCSI (SAS) interface.

Many data storage device types – including floppy, MO, tape and HDD – adopted SCSI. However, above, the word ‘standardised’ must be taken with a pinch of salt because OEMs did not always implement the full standard. For example, they often retained just the SCSI command protocol or the SCSI architectural model. Moreover, many SCSI drives were designed with a specific host in mind, and the latter would only interface with that exact model number (see figure 1).

Figure 1 – Above, this Fujitsu SCSI HDD was manufactured in the 1990s to fit a 1980s design for an IBM host computer. The drive has a standard 50-pin connector for data and control, and a 4-pin Molex connector for power. However, the positions of the connectors are such that they will mate only with corresponding connectors in the host’s chassis.

The unavailability of a new or reconditioned drive need not mark the end of the hosts system’s life, though.

Emulation

A number of companies are specialising in the design and manufacture of solid-state-based storage devices that can replicate the behaviour of these yesteryear units, even if their communications protocols were modified to make them unique to a host.

How is this done? Some details of the drive and its interface might be available online. However, in Solid State Disks Ltd’s (SSDL’s) case the company had to develop techniques to interrogate working drives because the level of information available online was insufficient to create emulations compatible with a number of host systems.

Alternatively, specialised analysis equipment can be taken to a host system and placed between it and the drive so that signal timings can be captured and programmed into the emulator. This is a worst-case scenario though, as extreme care must be taken when handling a drive that has become fragile over the years – but which is still in use within a host, is relied upon and there’s no backup/alternative immediately to hand.

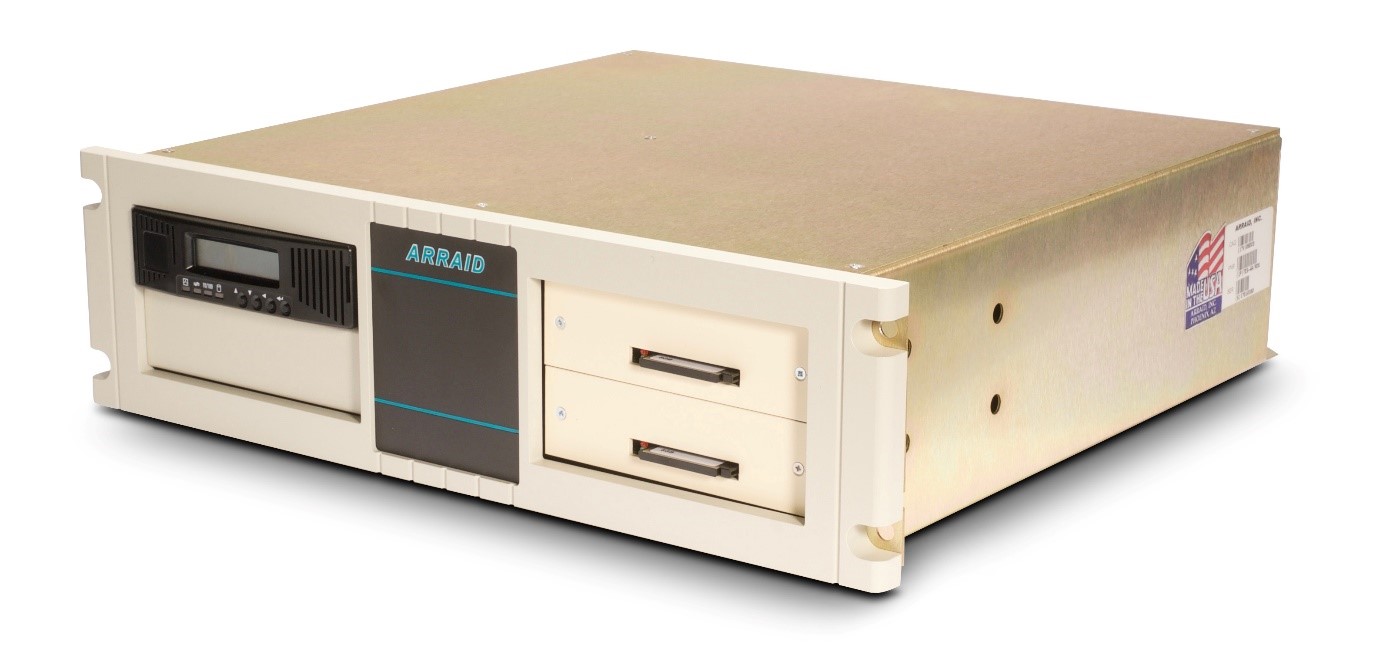

In essence, an emulator (like the one shown in Figure 2) for virtually any 1980s/90s drive can be created though it often requires more than simply adopting the same connector configuration and emulating the communication protocol.

Figure 2 – Above, a solid-state-based SCSI drive with dual CF cards.

Legacy drives are for the most part based on logical blocks, where the exact encoding of the data onto the disk is handled internally by the storage device. For some classes of device, such as ESDI or floppy, the encoding has to be implemented within the storage device’s firmware. This is a complex operation that can only be achieved by reverse engineering the particular implementation, including a detailed low-level examination of the format written to the media (which sometimes varies across the surface).

Also, the emulator may need to be formatted – in much the same way a USB stick needs to be formatted to at least FAT32 for use with Windows, for example. In addition, some hosts will expect a new drive to be filled entirely with logic zeros. Others will require the old data to be present on the new drive, in which case it needs to be copied. Again, care must be taken as the old drive will most likely be fragile.

The New Storage Medium

Because emulators have the same physical connector, interface protocols, memory maps and formatting (and if necessary, data already preloaded), the host system does not need to be modified. It will treat the new drive as if a replacement original had been installed, with the added benefit that reliability is greatly improved because solid-state has no moving parts. It draws less power too.

The storage media used in emulators tends to be industrial grade Compact Flash (CF) cards, which can be removed and treated like floppy disks, for example, but are far more robust. And if the emulator is replacing an HDD, a CF card is still the storage media; hidden behind a plate so that it cannot be removed. Note, the use of industrial grade CF cards also assures longer-term availability than its commercial equivalent.

Based on the end application there are a few things to consider when deciding on the CF card’s capacity and technology. Though solid-state drives have no moving parts, the memory will wear as a result of program-erase (PE) cycles.

Flash memory is typically NAND flash, of which there are different types. Single-level cell (SLC) technology stores one bit per cell and is the fastest type. Multi-level cell (MLC) stores two bits per cell, thus providing double the storage capacity. However, that doubling of capacity and a cheaper memory comes at the expense of speed (MLC is slower) and a greatly reduced (circa 30x) number of PE cycles; 100,000 for SLC but only 3,000 for MLC.

Saving the Day

As mentioned, a solid-state-based emulator can replicate the behaviour of virtually any 1980s or 1990s drive. Also, the use of modern technology introduces many new possibilities. For instance, the emulator shown in Figure 2 has an Ethernet port. This means it can be networked and accessed remotely; and some emulator OEMs have Windows-based memory management software for hot-backups and system recovery etc.

However, obsolescence is a moving target, and there are systems in use today that have already had their original drives replaced with an emulator which itself has since become obsolete. Accordingly, emulator OEMs must themselves keep on top of obsolescence.

Media contact:

Amanda Warrilow, Communications Officer

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel: +44 (0)1522 789000